Simulation and optimization of casting, rolling and heat treatment processes for competitive production of topmost steels

B. Filipič, T. Tušar, M. Mlakar

Funded by the Slovenian Research Agency and co-funded by the Štore Steel company, this project was dealing with multiscale through-process modeling of the steel production sequence consisting of continuous casting, rolling, and heat treatment. Our role in the project was to formulate and provide a tool for solving the problem of tuning the process parameter settings for continuous casting to result in the highest possible quality of cast steel.

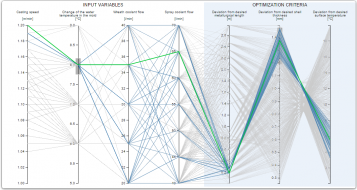

We designed and implemented a program that accepts boundary constraints and discretization steps of the considered process parameters, and boundary constraints and target values of the selected metallurgical criteria as input. Since the criteria are conflicting, the program returns a set of trade-off solutions according to the principles of multiobjective optimization and displays them in parallel coordinates. Optimization is carried out using the DEMO (Differential Evolution for Multiobjective Optimization) algorithm, and the solutions are evaluated via an external numerical simulator of the casting process. The program is in use in the Štore Steel company.